Your partner for

Pharma Liquid Automation

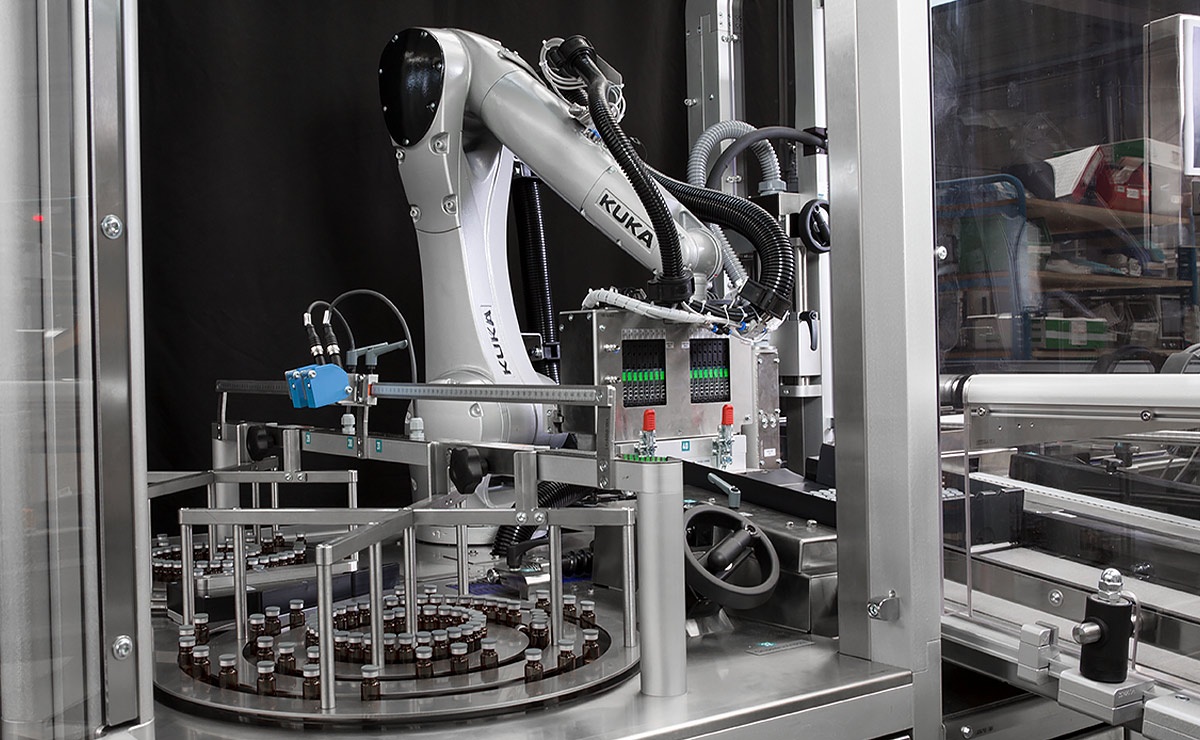

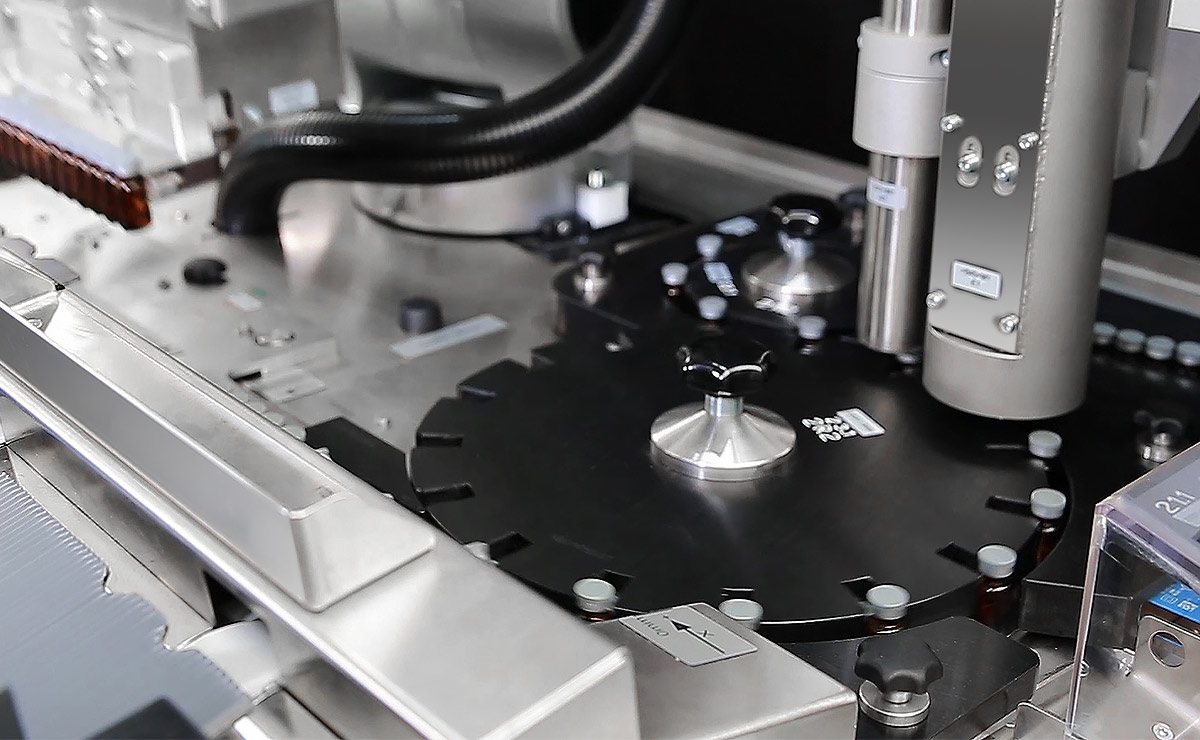

Robotic tray loading

Highest process safety in vial handling -

from manual to fully automatic operation

One of the world’s leading pharma producers of generics and biosimilars

needed a smart solution to load and monitor trays of vials fully

automatically. Previously, it had only been possible to load Akylux

trays of vials manually and process steps in this connection usually

involved substantial risks and manpower. The customer obviously assigned

high priority to the safe automated handling of vials for high-quality

pharmaceuticals. After the loading process, the trays of vials are first

put in quarantine before being processed further.

Main focus was placed on process safety, gentle handling of the product, protection against mix-ups and automatic in-process control. In times where prices are regulated in the pharmaceutical industry high economy efficiency was a relevant aspect and the low space available in the line installation was yet another challenge.

Main focus was placed on process safety, gentle handling of the product, protection against mix-ups and automatic in-process control. In times where prices are regulated in the pharmaceutical industry high economy efficiency was a relevant aspect and the low space available in the line installation was yet another challenge.

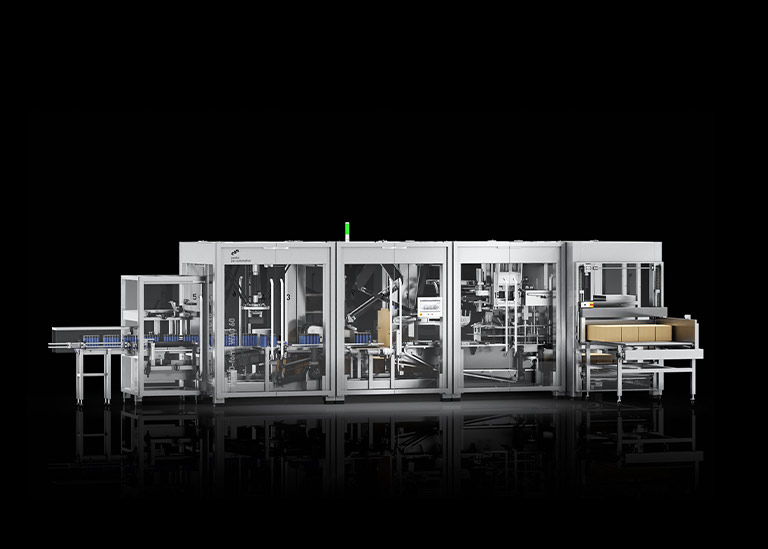

PEWO-flex

Robotic Tray Loader

Protection against mix-ups with non-labeled productsControlling mix-ups with non-labeled vials had to be implemented by marking a data matrix code on the lids with invisible ink. Incorrectly marked vials needed to be detected and rejected reliably by a camera system. Among other things, this valid process prevents potential product mix-ups which is vital when products are not labeled. A fully automatic in-process control was also implemented.

Quick project implementation and qualification

The project involving three machine units was realized within a period of only 8 months. Following a successful qualification phase based on the GMP guideline of the EU, annexes 11, 15, and ICH Q9, the three ordered units were put into a three-shift production. pester pac automation’s robotic tray loading solution for the automation of vial handling provided the customer with a customized concept which completely met all specified requirements.

Process

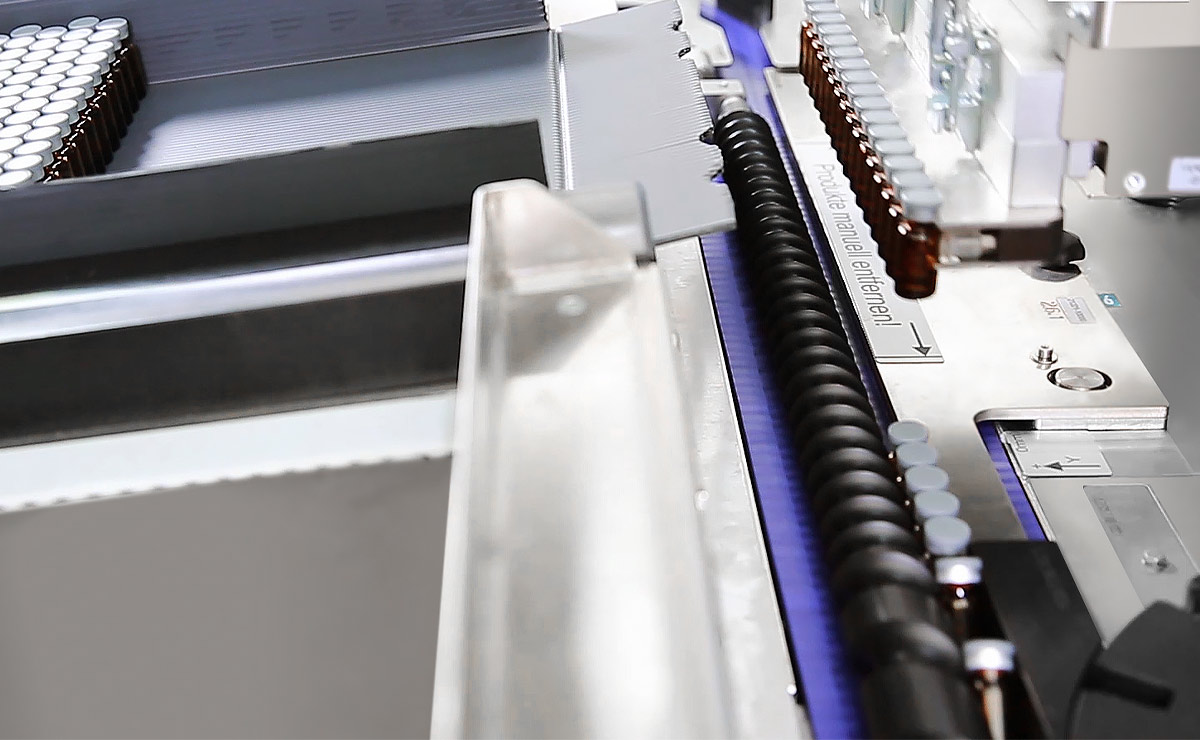

- Feeding of non-labeled vials via sorting plate or infeed conveyor

- Control and rejection of lying vials

- Marking of caps with invisible data matrix UV code

- Control and rejection of faulty products via camera system

- Transfer of vials via transport screw to ensure gentle product handling

- Feed of empty Akylux trays in loading station

- Loading of up to 200 vials/minute into trays via robot

- Optionally equipped with in-process control

- Smart, economical vial handling solution

- Compact, easy-to-clean GMP design

- Intuitive operation of machine via HMI tangius 4.2

- Consistent control system with integrated camera

- Quick format change through low number of format change parts

- High process safety

- High efficiency

Rainer Röcker

Senior Manager Pharma Liquid

Phone +49 (0) 83 34 / 607-553

Mobile +49 (0) 151 / 42 482 696

rainer-roecker@pester.com

www.pester.com

Senior Manager Pharma Liquid

Phone +49 (0) 83 34 / 607-553

Mobile +49 (0) 151 / 42 482 696

rainer-roecker@pester.com

www.pester.com

pester pac automation -

your innovative partner for

pharma liquid automation

Should you require further information

or consultation please contact your pharma

liquid expert: