Your partner for

Pharma Liquid Automation

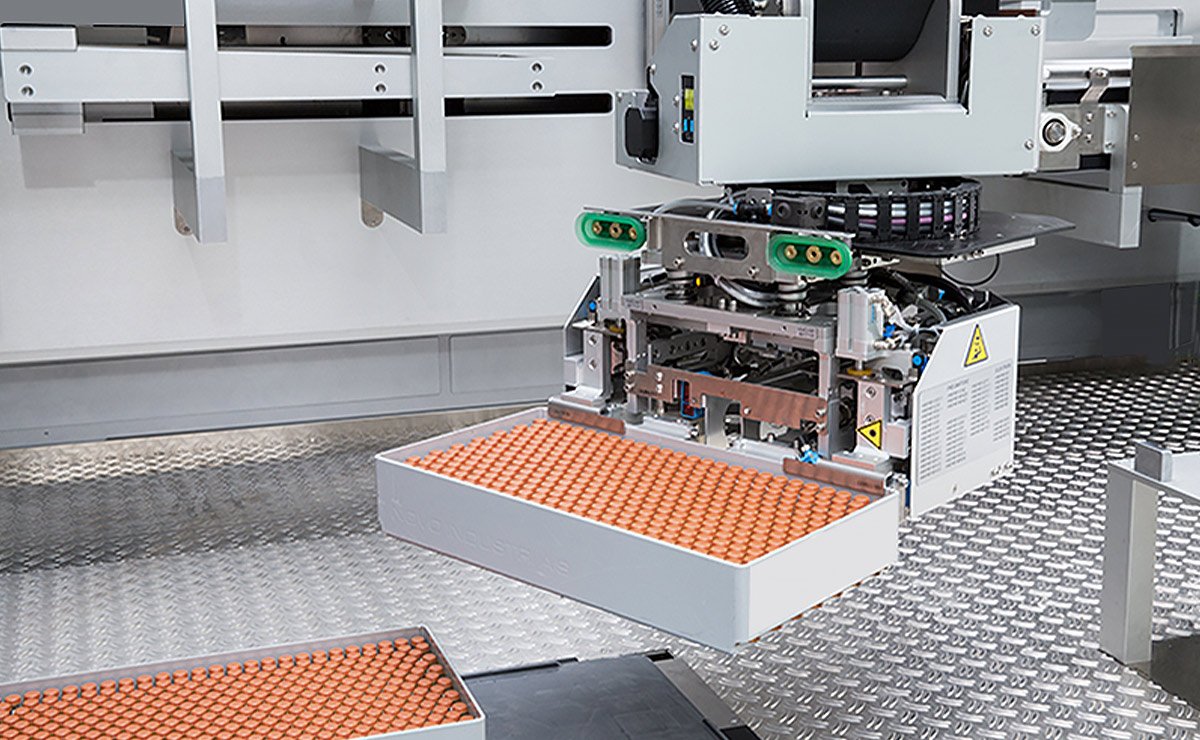

Robotic tray deloading

100% process reliability

for your vaccine packaging

Fully automatic feeding of vials, carpules and syringes containing highly sensitive vaccines

The world is eagerly awaiting a COVID-19 vaccine to be brought to market in 2020. Starting production quickly with huge quantities will require fully automatic and valid processes. Manual process steps often represent bottlenecks that slow a highly efficient, valid production down. Taking into account the requirements of the digital world and Pharma 4.0, are your processes fully automatic and primed for handling and packaging highly sensitive products? Now is the right time to take the next step towards the future – with the solutions offered by Pester.

Pester already successfully implemented the highly demanding requirements of a leading insulin and vaccine manufacturer. The task involved depalletizing carpules from trays arriving from a filling process, monitoring the positions with camera systems and safely feeding the products to the next process step, a labeler, without interruption. Be a cut above the rest with our pharma liquid solutions. Define the requirements for your vaccine packaging of tomorrow and we will implement them today.

The world is eagerly awaiting a COVID-19 vaccine to be brought to market in 2020. Starting production quickly with huge quantities will require fully automatic and valid processes. Manual process steps often represent bottlenecks that slow a highly efficient, valid production down. Taking into account the requirements of the digital world and Pharma 4.0, are your processes fully automatic and primed for handling and packaging highly sensitive products? Now is the right time to take the next step towards the future – with the solutions offered by Pester.

Pester already successfully implemented the highly demanding requirements of a leading insulin and vaccine manufacturer. The task involved depalletizing carpules from trays arriving from a filling process, monitoring the positions with camera systems and safely feeding the products to the next process step, a labeler, without interruption. Be a cut above the rest with our pharma liquid solutions. Define the requirements for your vaccine packaging of tomorrow and we will implement them today.

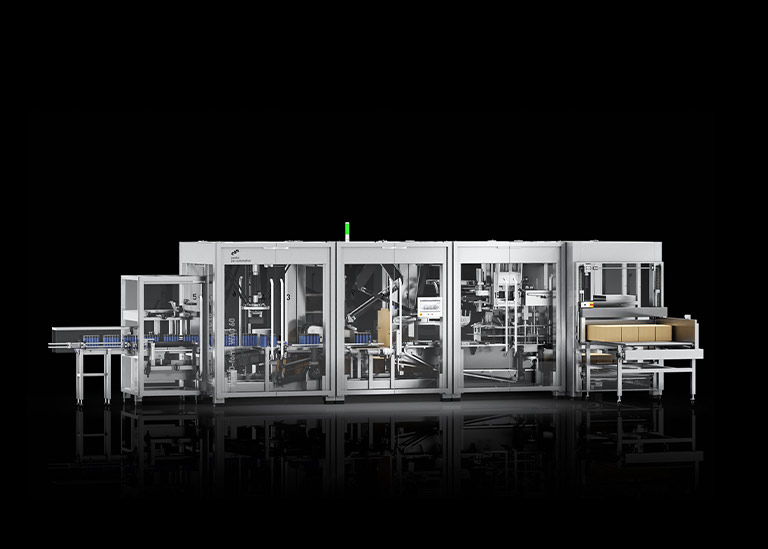

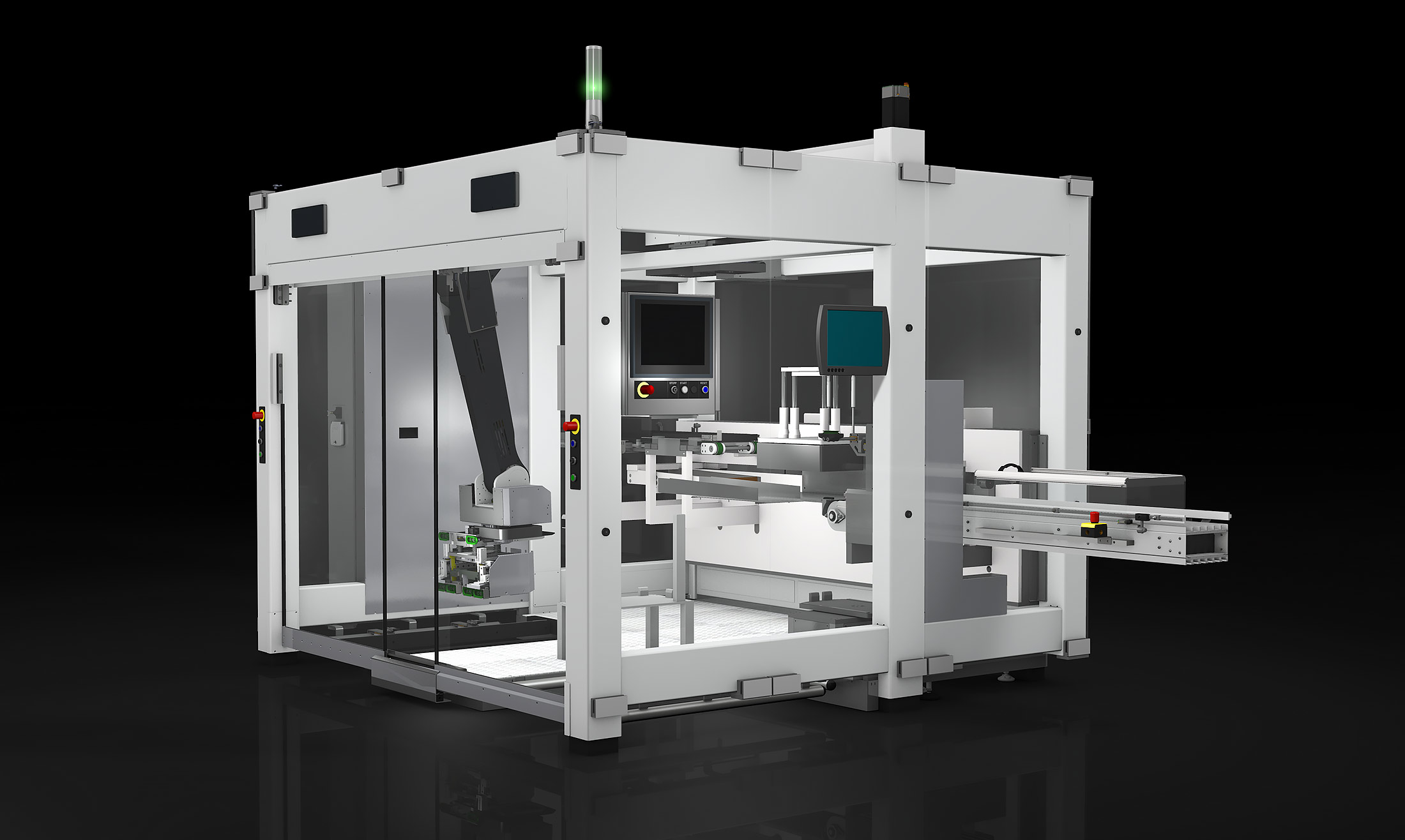

PEWO-depal 5.2 Compact

Robotic Tray Deloader

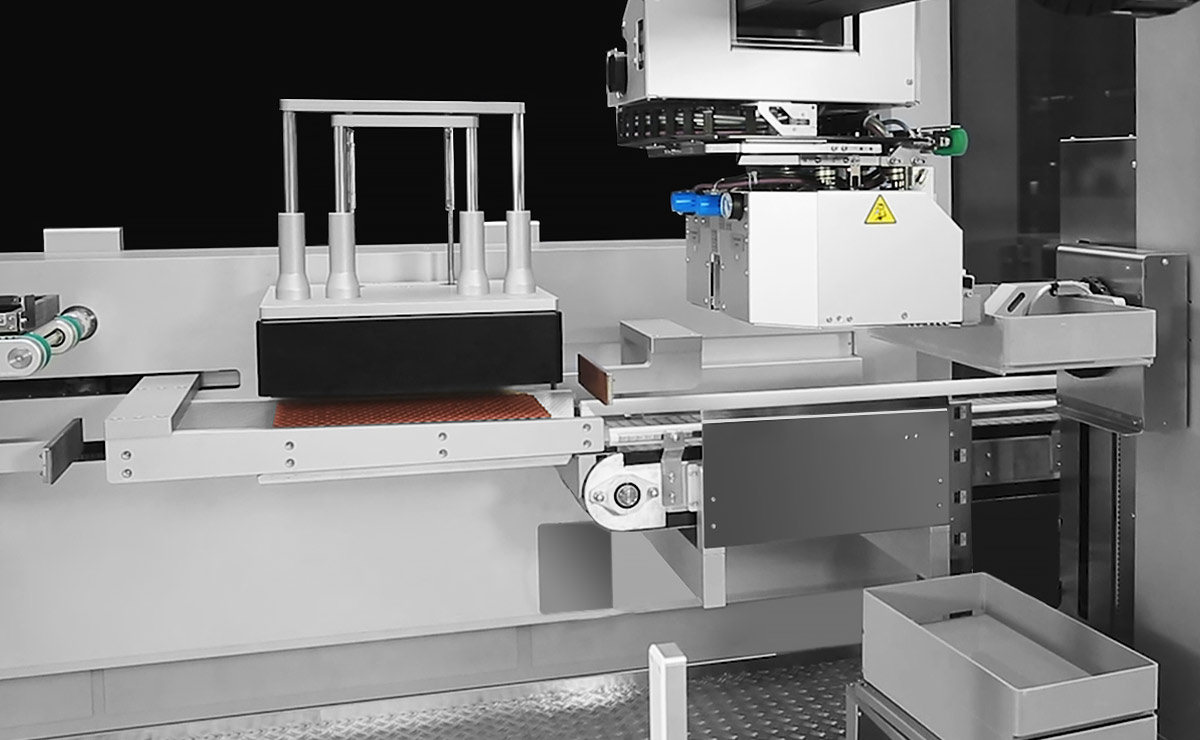

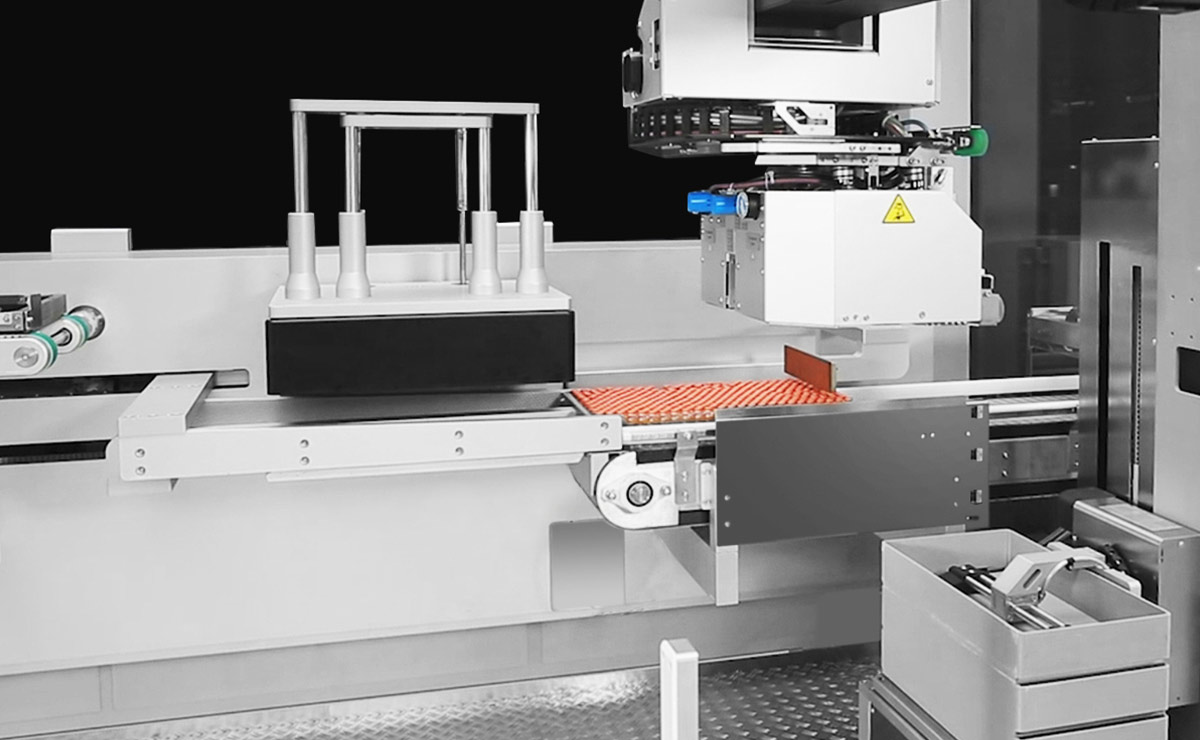

Protection against glass breakage due to a unique deloading processBy using Pester’s new deloading system, sensitive products are safely transferred from rigid plastic trays to the next process step without separately touching or mechanically stressing the individual products. Carpules are precisely guided from all four sides and hence safely transferred to the next process step without them falling over.

Prevention of production downtime due to missing products

The intelligent buffer system enables filled trays to be stored temporarily in the depalletizer, thus allowing the operator enough time to change the pallets. In the event that a tray contains a fallen carpule, it is detected reliably by a camera and the complete tray is consequently rejected. The robot seamlessly takes up the next tray, thus ensuring a reliable product flow.

Fast project implementation and commissioning

Thanks to our fast quotation and project planning stage, projects such as these are realized within only 8 months. With Pester’s fully automatic pharma liquid solutions robotic tray loading and robotic tray deloading and corresponding end-of-line packaging solutions, you will master the task in compliance with GMP, reliably and cost-effectively. From pallet to pallet.

Your process

- Insertion of pallets with filled plastic trays in Pester depalletizer

- Pick-up of trays of carpules via robotic tray deloading

- Position control via camera, including rejection

- Product-friendly feeding of up to 600 carpules to downstream labeler

- Fully automatic cost-effective production

- Highest process reliability

- Unmanned, continuous carpule feeding process

- No glass breakage

- Ongoing process without interruption due to missing or incorrectly positioned products

- Maximum performance due to omittance of manual process steps

- Modular, highly flexible system

- All process steps are able to be validated in compliance with EU GMP Directive, annex 11,15 and ICH Q9

- No production stop during pallet change

- Intuitive operation of machinery with tangius 4.2 HMI

- Quick format change due to low number of format parts

Rainer Röcker

Senior Manager Pharma Liquid

Phone +49 (0) 83 34 / 607-553

Mobile +49 (0) 151 / 42 482 696

rainer-roecker@pester.com

www.pester.com

Senior Manager Pharma Liquid

Phone +49 (0) 83 34 / 607-553

Mobile +49 (0) 151 / 42 482 696

rainer-roecker@pester.com

www.pester.com

pester pac automation -

your innovative partner for

pharma liquid automation

Should you require further information

or consultation please contact your pharma

liquid expert: