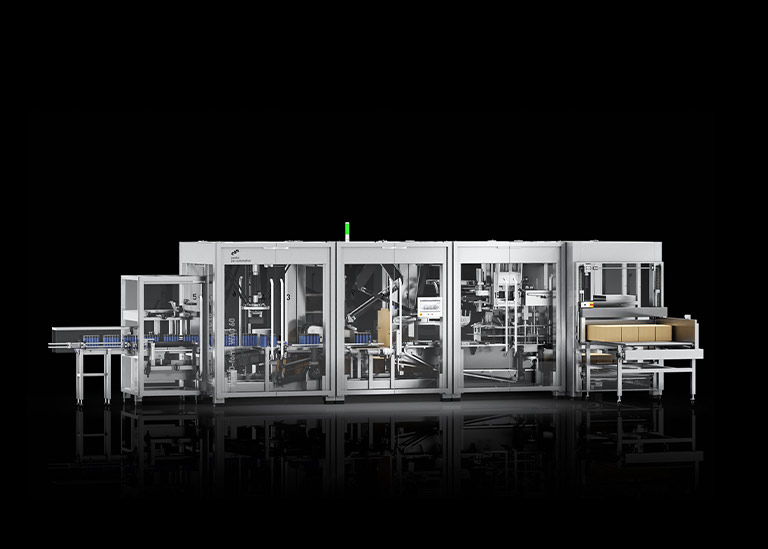

PEWO-form TLP Compact

Combined top loader and palletizer of the latest generation

Experience flexible packaging for pharmaceutical bottles, folding cartons, vials and inhalers to ready-for-sale packages with outserts. Dynamic, powerful and highly productive, the integration of state-of-the-art Track & Trace systems guarantees unfailing process safety.

Benefits

- New generation of human-machine communication

- Interactive 3D visualization

- Intuitive machine operation via 15" multi-touch display

- New modern GMP pharma design

- Doors made of safety glass with soft closing function: durable, antistatic, scratch-proof

- Transparent control cabinet

- Customized solution depending on installation situation

- Pre-defined interfaces for integration of Track & Trace system

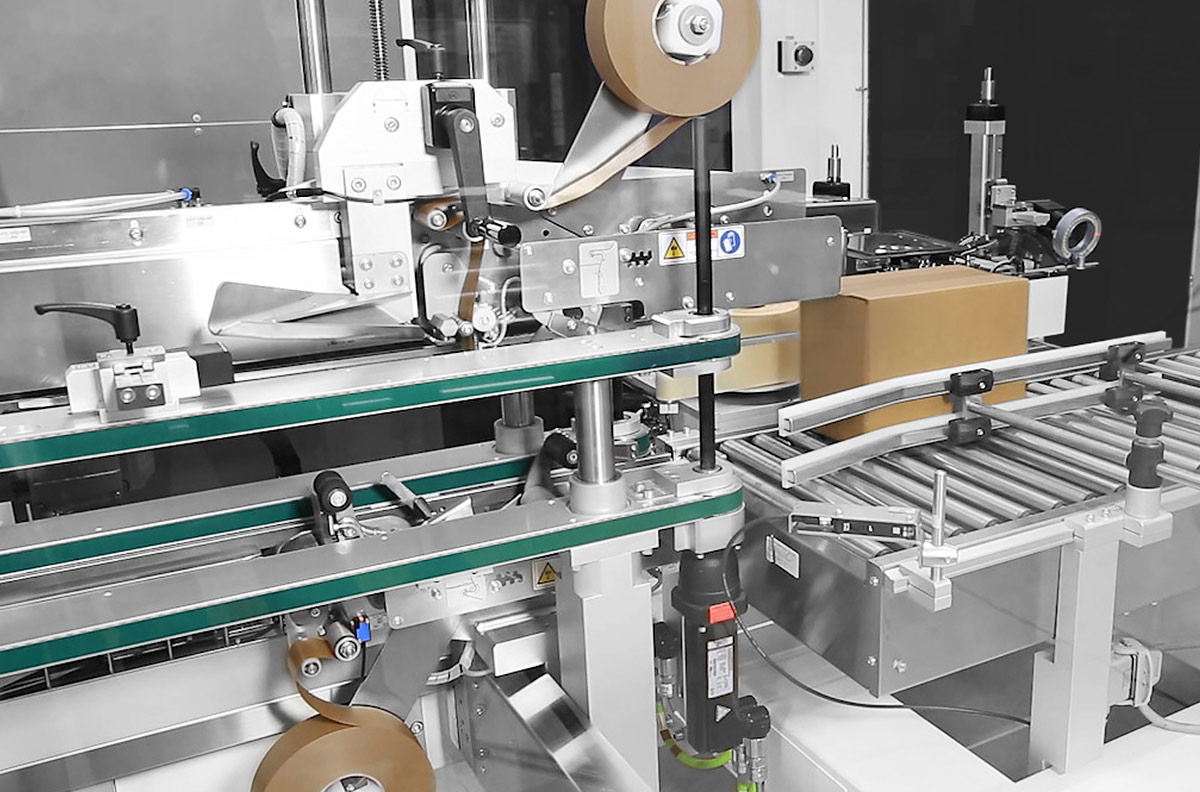

- Innovative labeling technology

- Robotics: pester pac robot 2 and pac robot P 15

- Case magazine for simple loading

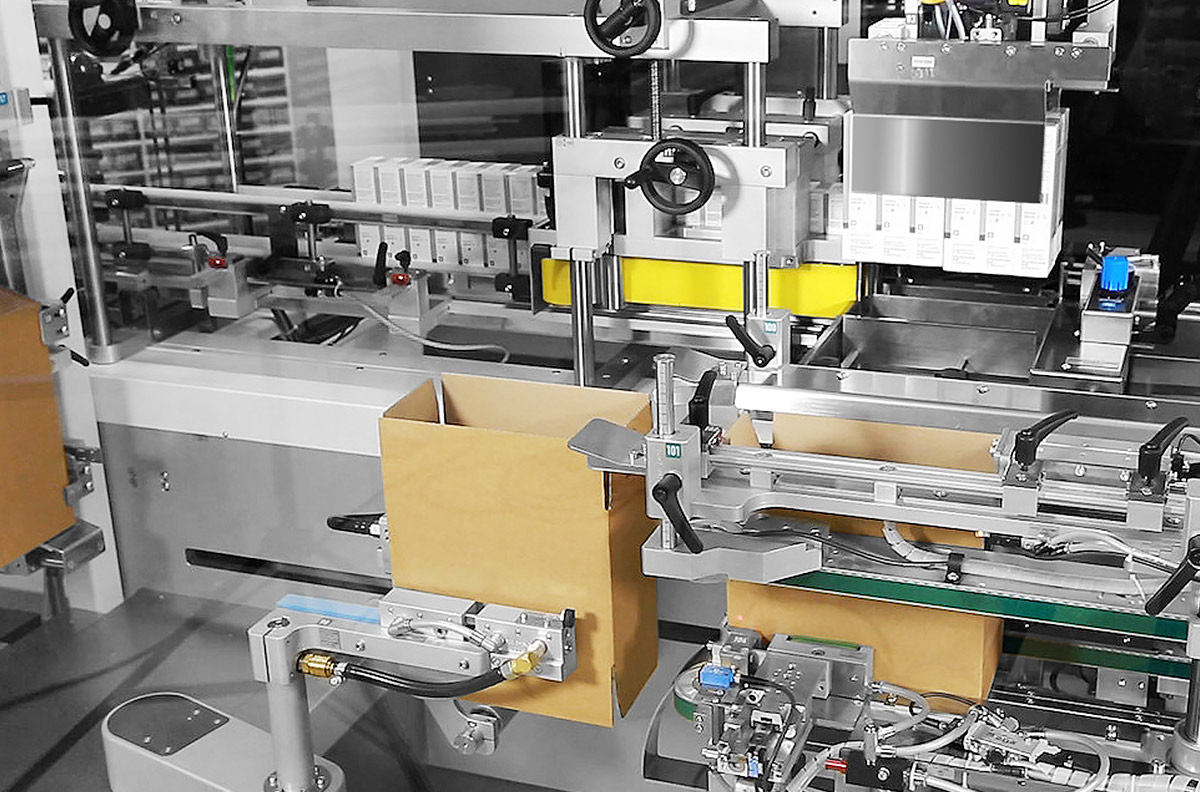

- Reliable case handling with innovative case extraction via cascade system

- Ergonomic and fail-safe – new case magazine with zero access standard and user-friendly hand wheel adjustment

- High-precision case transport by means of 4 servo-controlled toothed belts with lugs

- Prepared for automatic format changeover

- RFID format part detection on request

- Simple, reproducible format changeover

- New, intelligent safety concept

- IPC (in-process control)

- Prepared for connection to AGV systems

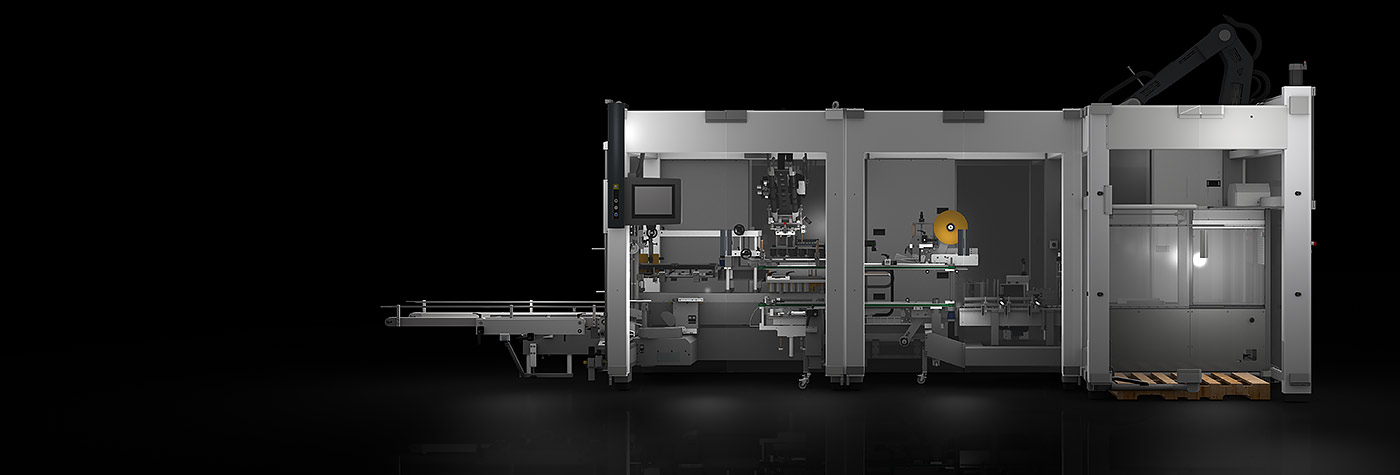

PEWO-form TLP 2 Compact

| Machine dimensions | 6700 x 3370 x 2350 mm [L x W x H] |

| Ceiling height | 3250 mm to allow for operating range of robot |

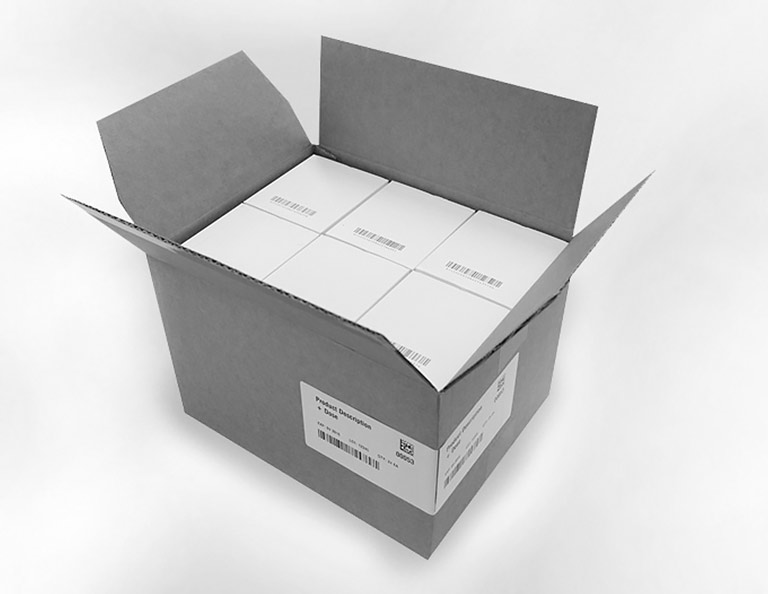

| Case type | American case |

| Sealing method | tape / hotmelt glue |

| Min. format range | product 20 x 20 x 60 mm [L x W x H] case 230 x 230 x 170 mm [L x W x H] |

| Max. format range | product 440 x 200 x 250 mm [L x W x H] case 450 x 350 x 350 mm [L x W x H] |

| Performance | up to 8 cases/min. |

| Control system | Schneider Electric PacDrive 3 / Rockwell Automation (Allen-Bradley) |

| Pallet size | 1200 x 800 mm - 1220 x 1016 mm (48" x 40") |

| Max. palletizing height | 1400 mm (including pallet) |

PEWO-form TLP 3 Compact

| Machine dimensions | 6700 x 3370 x 2350 mm [L x W x H] |

| Ceiling height | 3250 mm to allow for operating range of robot |

| Case type | American case |

| Sealing method | tape / hotmelt glue |

| Min. format range | product 20 x 20 x 60 mm [L x W x H] case 230 x 230 x 170 mm [L x W x H] |

| Max. format range | product 440 x 200 x 250 mm [L x W x H] case 600 x 400 x 400 mm [L x W x H] |

| Performance | up to 8 cases/min. |

| Control system | Schneider Electric PacDrive 3 / Rockwell Automation (Allen-Bradley) |

| Pallet size | 1200 x 800 mm - 1220 x 1016 mm (48" x 40") |

| Max. palletizing height | 1400 mm (including pallet) |

Format range subject to feeding and collating system and features of machine.

Your continent

Your country

Your topic

Service excellence is the result of competence, passion and commitment. We are there whenever you need us!

Gerhard KathanDirector Customer Service

Your Service

Partner for

Top Performance

"You expect a service partner you can always rely on, who is familiar with your needs and offers fast answers to your questions? A partner who is always at your side whenever you need support and focusses on achieving the maximum performance for you in a team?

We accompany you throughout the entire lifetime of your machine from the initial concept to the fully automatic packaging process. Our experts provide you with the right packaging solution and comprehensive customized service for any individual phase - all from one source. Benefit from our individual support close at hand. Over the whole life-cycle of our machines we ensure highest productivity, security and maximum availability for your Pester machine, wherever you need it."