Profile

Inspired by technology

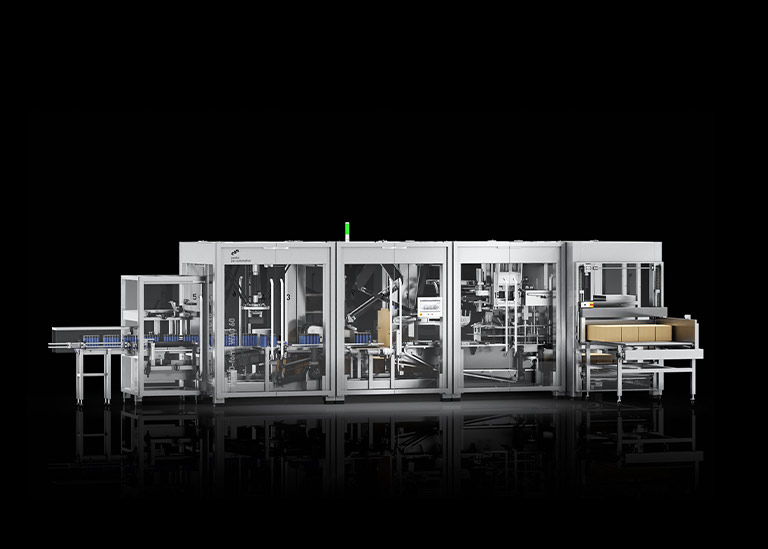

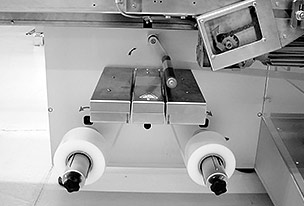

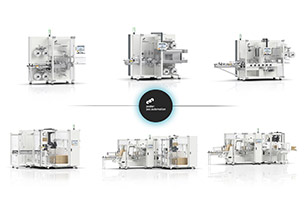

We have been giving new impetus to end-of-line pharmaceutical and consumer goods packaging for more than 50 years. pester pac automation stands for innovation and the development of intelligent cutting-edge machine concepts from film wrapping and case packing through to palletizing.

Today, pester pac automation ranks among the leading companies in this sector. Over 8,000 Pester machines and lines are proving their intelligence daily at multinational companies in the pharmaceutical and consumer industry around the globe.

Customers all over the world appreciate the high quality of our machine program. Pester machines convince on account of their superior quality, outstanding performance and economical life-cycle costs. Individual service, customized engineering and tailor-made turn-key solutions demonstrate the leading-edge of our technology.

What makes Pester stand out? The unique quality of the relationships we maintain with our customers, partners and suppliers. Worldwide, some 950 employees, eight subsidiaries and 35 representatives in 80 countries are all part of a dynamic network whose only objective is to provide our customers with the optimum packaging process.

Today, pester pac automation ranks among the leading companies in this sector. Over 8,000 Pester machines and lines are proving their intelligence daily at multinational companies in the pharmaceutical and consumer industry around the globe.

Customers all over the world appreciate the high quality of our machine program. Pester machines convince on account of their superior quality, outstanding performance and economical life-cycle costs. Individual service, customized engineering and tailor-made turn-key solutions demonstrate the leading-edge of our technology.

What makes Pester stand out? The unique quality of the relationships we maintain with our customers, partners and suppliers. Worldwide, some 950 employees, eight subsidiaries and 35 representatives in 80 countries are all part of a dynamic network whose only objective is to provide our customers with the optimum packaging process.

Family-owned company

in the 4th generation

Top 100 Employers in Germany

(17th place), 1st place in the Allgäu

(Great Place to Work® Award 2021)and Top Company 2023 (kununu)

8,000

packaging units

worldwide

80% top pharma

and consumer goods

companies rely

on the Pester technology

Around 950 employees

worldwide

Company founded by

Emil Pester in 1888

FACTS

Global

Worldwide, some 950 employees, eight separate sales and service companies and 35 representatives in 80 countries are all part of a dynamic network. This is how we guarantee close relationships to our customers and individual on-the-spot service all over the world.

pester pac automation

Welcome to our corporate head office in Wolfertschwenden in the heart of the Allgaeu, Bavaria. The modern administration and production facility received an award for its architecture and sustainability in 2001. Our customer service, parts manufacturing and center for trainees are also located in close vicinity at four different sites. Our Business Unit pester consumer relocated to new premises in 2017.

Welcome to our corporate head office in Wolfertschwenden in the heart of the Allgaeu, Bavaria. The modern administration and production facility received an award for its architecture and sustainability in 2001. Our customer service, parts manufacturing and center for trainees are also located in close vicinity at four different sites. Our Business Unit pester consumer relocated to new premises in 2017.

pester ag Switzerland

Based at Tägerwilen, pester ag Switzerland has been supporting the international focus and global marketing activities of pester pac automation GmbH since 2006. We are the direct contact persons for customers in Austria and Switzerland.

Based at Tägerwilen, pester ag Switzerland has been supporting the international focus and global marketing activities of pester pac automation GmbH since 2006. We are the direct contact persons for customers in Austria and Switzerland.

pester usa

With our own sales and service subsidiary we have been catering for the American market since 1998. Our new customer center is located in Charlotte, Huntersville, North Carolina since 2020. Currently, 14 specialists attend to the needs of our customers in North America, Canada and Puerto Rico and vouch for the quality standards of Pester worldwide. Our own spare parts depot warrants fastest availability and reliable service. Over 1000 Pester units and lines in operation all over the USA prove our customized technology.

With our own sales and service subsidiary we have been catering for the American market since 1998. Our new customer center is located in Charlotte, Huntersville, North Carolina since 2020. Currently, 14 specialists attend to the needs of our customers in North America, Canada and Puerto Rico and vouch for the quality standards of Pester worldwide. Our own spare parts depot warrants fastest availability and reliable service. Over 1000 Pester units and lines in operation all over the USA prove our customized technology.

pester france

We have been catering for the French market with our own sales and service subsidiary since 1998. At present, 5 specialists attend to our customers' needs in France and vouch for the quality standards of Pester worldwide. Our own spare parts depot warrants fastest availability and reliable service. Over 500 Pester units and lines in operation all over France prove our customized technology.

We have been catering for the French market with our own sales and service subsidiary since 1998. At present, 5 specialists attend to our customers' needs in France and vouch for the quality standards of Pester worldwide. Our own spare parts depot warrants fastest availability and reliable service. Over 500 Pester units and lines in operation all over France prove our customized technology.

pester uk

We have been catering for the British and Irish markets with our own sales and service subsidiary near London since 2004. At present, 6 specialists attend to our customers' needs on site and vouch for the quality standards of Pester worldwide. Our own spare parts depot warrants fastest availability and reliable service. Over 600 Pester units and lines in operation all over Ireland and the UK prove our customized technology.

We have been catering for the British and Irish markets with our own sales and service subsidiary near London since 2004. At present, 6 specialists attend to our customers' needs on site and vouch for the quality standards of Pester worldwide. Our own spare parts depot warrants fastest availability and reliable service. Over 600 Pester units and lines in operation all over Ireland and the UK prove our customized technology.

pester benelux

We have been catering for the markets in Belgium, the Netherlands and Luxemburg with our own sales and service subsidiary since 1997. Some 200 Pester units and lines locally in operation prove our customized technology.

We have been catering for the markets in Belgium, the Netherlands and Luxemburg with our own sales and service subsidiary since 1997. Some 200 Pester units and lines locally in operation prove our customized technology.

pester china

Pester China has been catering for the Chinese market since 2004. Our own sales and service company is located in Shanghai. At present, 15 specialists attend to our customers' needs on site and vouch for the quality standards of Pester worldwide. A separate spare parts center provides fast availability and a reliable service. Our customers include renowned companies in the pharmaceutical and healthcare industry.

Pester China has been catering for the Chinese market since 2004. Our own sales and service company is located in Shanghai. At present, 15 specialists attend to our customers' needs on site and vouch for the quality standards of Pester worldwide. A separate spare parts center provides fast availability and a reliable service. Our customers include renowned companies in the pharmaceutical and healthcare industry.

pester in asia

With our own branch office in Bangkok, Thailand, we have been catering for the markets in South East Asia since 2004 and vouch for the quality standards of Pester worldwide.

With our own branch office in Bangkok, Thailand, we have been catering for the markets in South East Asia since 2004 and vouch for the quality standards of Pester worldwide.

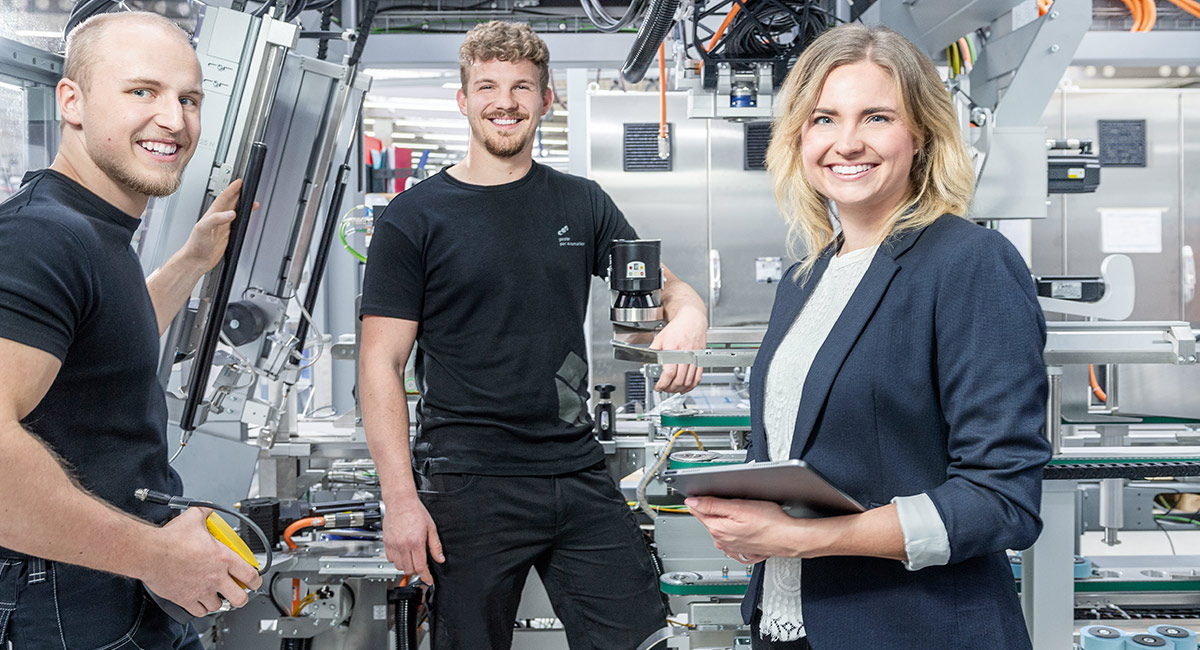

Values

Responsibility

We simply

always give our very best

Two principles are the basis of our actions:

1. Our customers' long-term success and happiness.

2. Our employees' lasting enthusiasm.

"Inspired by technology" - our innovative strength creates long-lasting values for our customers and environment. Achieving solid corporate growth through sustainable development is our commitment. Our comprehension of trendsetting sustainability is to promote economical, ecological and social responsibility.

With this in mind, we develop innovative and future-oriented packaging solutions by using our resources responsibly and placing emphasis on sustainable processes. Exceptional relationships with our customers, employees and business partners characterize us as a long-term trusted partner.

1. Our customers' long-term success and happiness.

2. Our employees' lasting enthusiasm.

"Inspired by technology" - our innovative strength creates long-lasting values for our customers and environment. Achieving solid corporate growth through sustainable development is our commitment. Our comprehension of trendsetting sustainability is to promote economical, ecological and social responsibility.

With this in mind, we develop innovative and future-oriented packaging solutions by using our resources responsibly and placing emphasis on sustainable processes. Exceptional relationships with our customers, employees and business partners characterize us as a long-term trusted partner.

Economic Responsibility

- High investment security and continued sound corporate growth

- Reliable long-term partnerships

- Efficient packaging solutions with economical life-cycle costs

Ecological Responsibility

- Permanent embedding of environmental principles in our quality management

- Development of sustainable packaging machinery with a long life time

- Responsible use of packaging materials and resources

- Constant research and development for ecological packaging materials

- 335,000 kg CO2 savings per year through the use of renewable sources of energy at our company headquarters

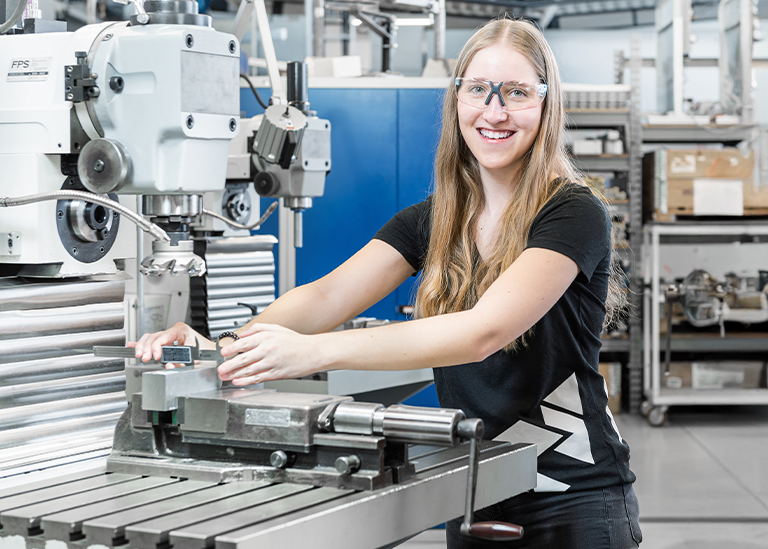

Social Responsibility

- As a family-owned company in the 4th generation, social responsibility enjoys high priority at Pester.

- Sustainable health management for our employees

- Promotion of regional and international social programs, charity projects and organizations

- Commitment in local and regional sport and cultural sponsorships

Initiative Blue Competence

We are Alliance Member of the Sustainability Initiative Blue Competence. Blue Competence (www.bluecompetence.net) is an initiative of the VDMA (www.vdma.org) for promoting and communication of sustainable solutions for the Mechanical Engineering Industry. By using the trademark "Blue Competence", we commit ourselves to these twelve Sustainability Guidelines of the Mechanical Engineering Industry.

www.bluecompetence.net/about

www.bluecompetence.net/about

Integrated Management System

Quality is our

passion

Our customers' happiness is our goal. Quality is the main focus in

all of our activities, and the basis for our long-term corporate

success. As the leader of technology in end-of-line packaging, it is our

responsibility to inspire our customers with packaging machines and

lines that incorporate the latest technology and the highest quality.

Reliable products, outstanding services and efficient processes are all part of our company's quality standard. Our goal is their constant improvement to ensure our customers' continual success.

Sustainable management, environmental protection and preservation of natural resources paired with our commitment to social, health and ethical responsibilities are our top priorities. Long-term relationships with our customers, partners, suppliers and employees are the foundation of our success. The active participation of all our employees in our integrated management system ensures Pester's sustainable growth.

Reliable products, outstanding services and efficient processes are all part of our company's quality standard. Our goal is their constant improvement to ensure our customers' continual success.

Sustainable management, environmental protection and preservation of natural resources paired with our commitment to social, health and ethical responsibilities are our top priorities. Long-term relationships with our customers, partners, suppliers and employees are the foundation of our success. The active participation of all our employees in our integrated management system ensures Pester's sustainable growth.

Integrated Management System

Our goal is to constantly evolve sustainability in our company. We have

implemented an integrated management system for quality, environment,

energy and occupational health and safety to optimize and continuously

develop our organization and processes in this regard.

AEO-F Certification

Secure supply chain: Pester is AEO-F certified

The applicant proves its proficiency and diligence regarding compliance with the customs provisions.

AEO-S - Security

The company proves its compliance with customs safety factors to logistical and administrative procedures.

AEO-F - Customs simplifications/security

The company fulfils all requirements that have been stated in the AEO-C and AEO-S options.

pester pac automation GmbH is AEO-F certified.

- The objective of the AEO certification is to ensure supply chain security from the manufacturer of a product, to the end consumer.

- An Authorized Economic Operator is reliable and trustworthy.

- An operator with the AEO status is authorized to simplifications with regard to customs regulations and/or benefits at safety-relevant customs controls.

- The Authorized Economic Operator status is granted in three categories:

The applicant proves its proficiency and diligence regarding compliance with the customs provisions.

AEO-S - Security

The company proves its compliance with customs safety factors to logistical and administrative procedures.

AEO-F - Customs simplifications/security

The company fulfils all requirements that have been stated in the AEO-C and AEO-S options.

pester pac automation GmbH is AEO-F certified.