New stretching technology - safe handling of heat-sensitive products

Boost your packaging process efficiency with our unique sustainable stretching technology. Safe, secure and sustainable: Safe handling during packaging and transport for all heat-sensitive and flammable products. Innovative and efficient shelf-ready packaging solutions.

Safe, Secure and Sustainable:

Take your sustainability to a higher level

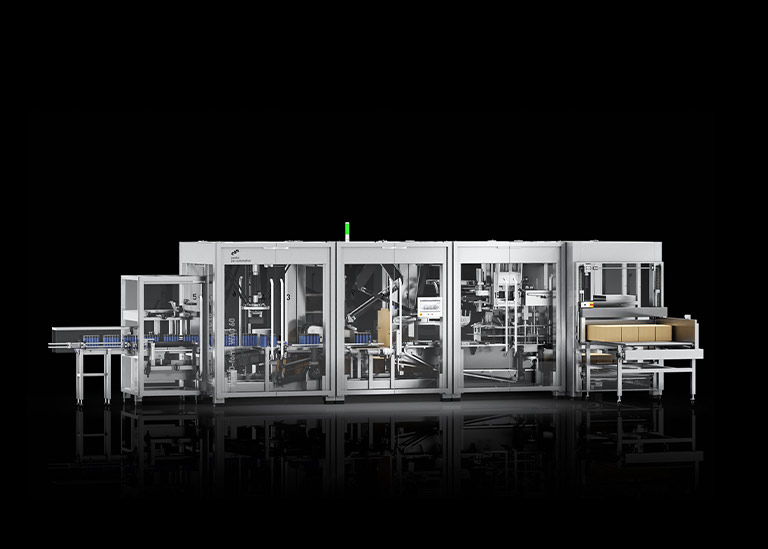

The first stretch bundler providing collations with shrink wrap properties without the need of a heat tunnel. Safe and secure shelf-ready packs, sustainable packaging process and secure transport - this is what you can expect when producing stretched bundles on the new Pester stretch bundling machine for collations with shrink wrap appeal.

Experience a new stage of safe and sustainable packaging technology which is ideal for all heat-sensitive or hazardous products, certified by DS Smith, testing center for hazardous materials. Compared to traditional shrink wrappers with the new Pester technology you will benefit from 75% energy savings and 50% material savings. As no heat tunnel is required you gain 30% more space with the reduced footprint.

Your benefits

Unique performance of up to 70 bundles/min. For example: When you run six-packs on a puck bottle line, you reach up to 420 bottles/min.

Shelf-ready packaging on smallest footprint

Compact solution for shelf-ready packaging with the new integrated Pester single-lane tray former. Stand-alone also available.

Safety first

Ideal for aerosol applications, heat-sensitive and flammable products. The new stretching technology provides safe and secure bundles without the need of a heat tunnel. Save costs by eliminating the need for costly safety protection add-ons.

Save money every day

Save up to 75% energy costs and 50% material costs compared to standard shrink bundlers.

Read more ...

Take your sustainability to a higher level

The first stretch bundler providing collations with shrink wrap properties without the need of a heat tunnel. Safe and secure shelf-ready packs, sustainable packaging process and secure transport - this is what you can expect when producing stretched bundles on the new Pester stretch bundling machine for collations with shrink wrap appeal.

Experience a new stage of safe and sustainable packaging technology which is ideal for all heat-sensitive or hazardous products, certified by DS Smith, testing center for hazardous materials. Compared to traditional shrink wrappers with the new Pester technology you will benefit from 75% energy savings and 50% material savings. As no heat tunnel is required you gain 30% more space with the reduced footprint.

Your benefits

- 75% energy savings

- 50% material savings

- 30% space savings

Unique performance of up to 70 bundles/min. For example: When you run six-packs on a puck bottle line, you reach up to 420 bottles/min.

Shelf-ready packaging on smallest footprint

Compact solution for shelf-ready packaging with the new integrated Pester single-lane tray former. Stand-alone also available.

Safety first

Ideal for aerosol applications, heat-sensitive and flammable products. The new stretching technology provides safe and secure bundles without the need of a heat tunnel. Save costs by eliminating the need for costly safety protection add-ons.

Save money every day

Save up to 75% energy costs and 50% material costs compared to standard shrink bundlers.

Read more ...